Preformed expansion joint fillers

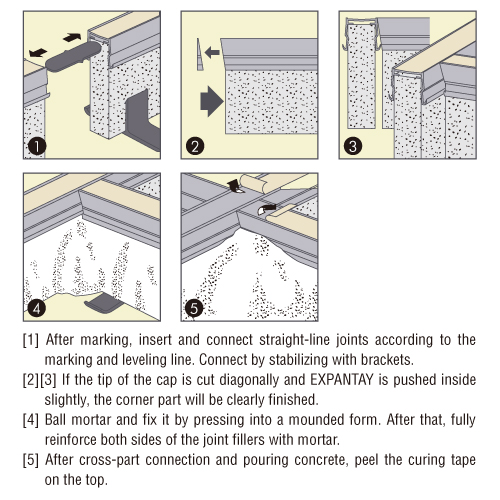

EXPANTAY

“Reliable finish,” “significant improvement in working efficiency,” and “superior cost performance”

The 5-stage EXPANTAY, an ideal combination of the characteristics of closed-cell polypropylene foam, butyl rubber, synthetic rubber (EPDM), stainless steel, glass fiber, and polyvinyl chloride, that surpasses conventional elastite joint fillers. This construction method now attracts attention as a method that is bringing a whole new perspective to the building industry.

There is a wide variety of needs for modern building components. Nevertheless, beautiful, functional, and labor-saving construction methods are a common thread among those needs. Rooftops are no exception. A hard look is also being given to joint fillers in their waterproof layer. The emergence of preformed expansion joint fillers that perfectly captures the needs of the times; beautiful finishes, outstanding physical functions, and labor-saving construction methods, which could not be satisfied by conventional products, has been much anticipated and created a sensation in the building industry.

///Points of EXPANTAY///

- 1. Shorterned work periods by labor saving and pollution-free construction methods with safety improved!

- 2. Commercialized by combining the advantages of five materials!

- 3. Excellent durability, weather resistance, heat resistance, waterproofing performance, and chemical resistance!

- 4. Beautiful finish with flexible follow-up

- 5. Wide variation for straight lines, corners, sizes, etc.

- 6. Stable quality secured by carefully selected materials

Details

-

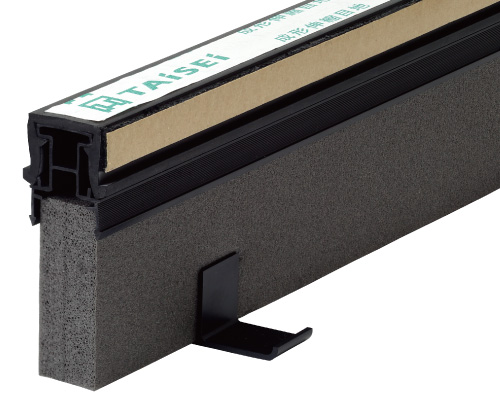

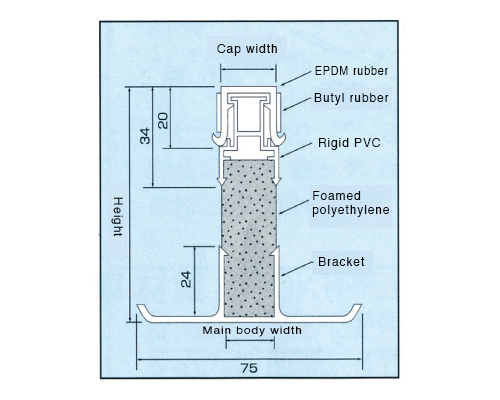

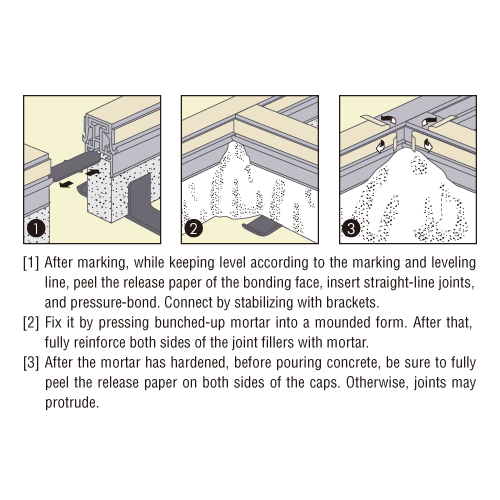

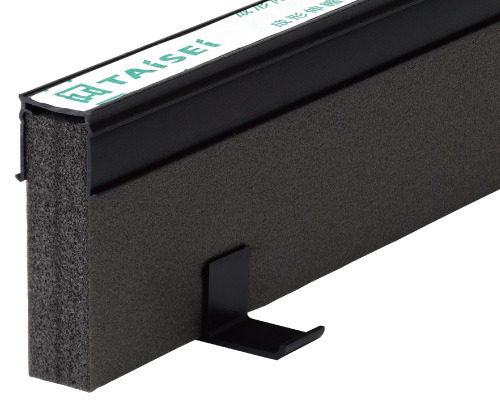

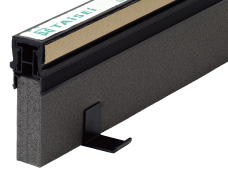

EXPANTAY TE type

First class that satisfies all requirements

The TE type, consisting of five stages offers various roles and exerts extraordinary power because of its composite effects. Therefore, it can be said to be a masterpiece that successfully satisfies all requirements for expansion joint fillers, including reversibility and waterproofing performance. The performance of the product has advanced even further than expected by covering plastic that excels in wear resistance and insulation and heat resistance with EPDM rubber that excels in weather resistance.

Adhesive layer type

- Principal use

- General buildings / Parking lots / Cold and tropical regions / Places where sealability is required (vehicles allowed)

- Major performance

- Wear resistance / Insulation / Heat resistance / Vehicles allowed / Excellent durability

- Accessories

- Straight-line joints (one per 1.5m) / Brackets (three per 1.5m)

*Bracket is not included with the TE40 type.

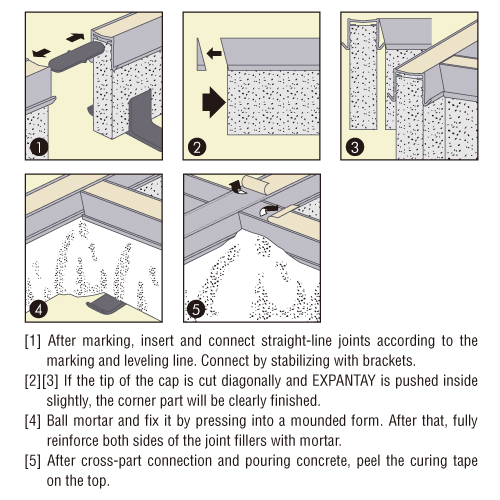

Standards (Unit: mm) Product name Cap width Main body width Height Length TE type 20 20 16 40~500 1,500 TE type 25 25 20 TE type 30 30 25 TE type 40 40 33 TE30 and TE40 made to order

- -Approved by the Preformed Expansion Joint Filler Manufacturers Association

- -Certified by the Public Buildings Association

- -Standardized by the Ministry of Land, Infrastructure, Transport and Tourism

-

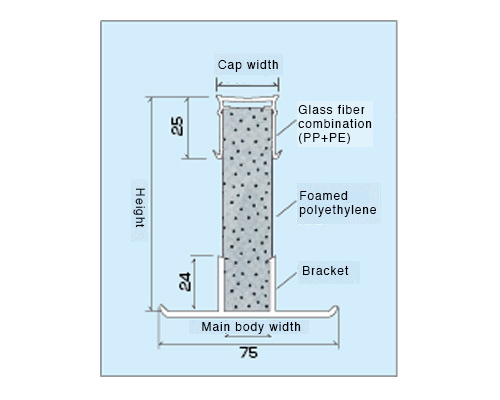

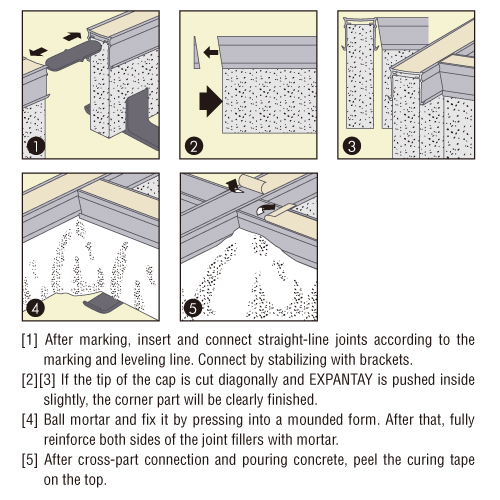

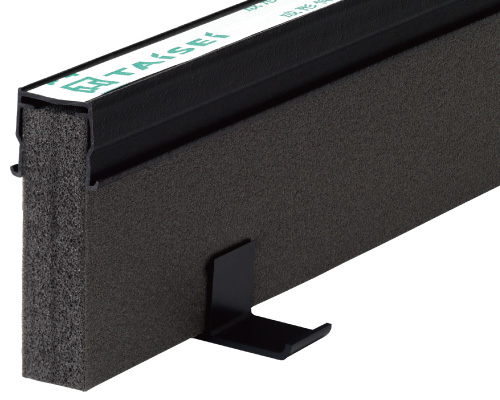

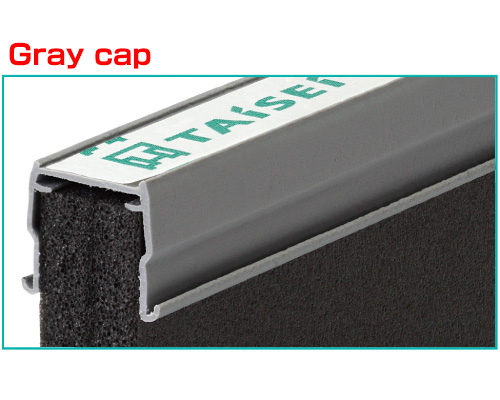

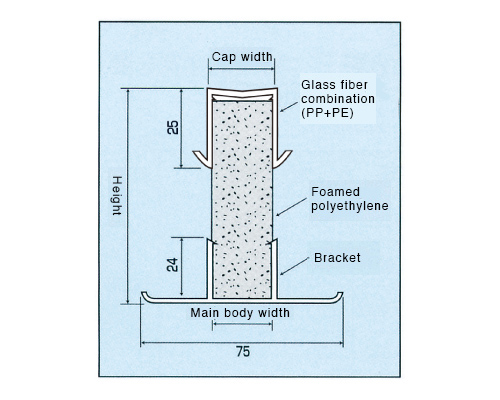

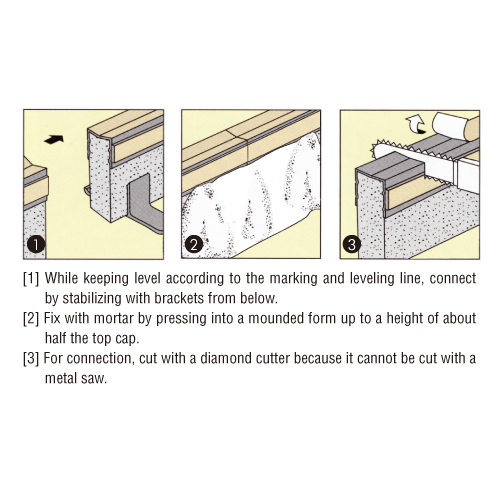

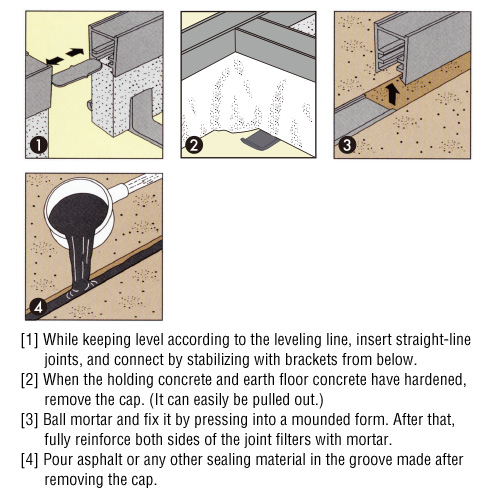

EXPANTAY TZ type

Joint filler excellent in preventing cracking and breaking up of concrete slabs

The curved portion on the side of the cap functions to prevent cracking and breaking up of concrete slabs and continuously maintain a construction-completed finish. Also, the combination of glass fibers improves shape stability, reduces shrinkage and warpage, and increases impact resistance. The cap can be cut with a cutter and increases workability. This preformed expansion joint filler allows for workability and economical efficiency with consideration given to concrete slabs.

Anchor type

- Principal use

- General buildings / Floors (concrete slabs) / Parking lots (at slow speeds)

Major performance - Major performance

- Shape stability / Impact resistance / Vehicles allowed (at slow speeds) / Excellent durability

- Accessories

- Straight-line joints (one per 1.5m) / Brackets (three per 1.5m)

Standards (Unit: mm) Product name Cap width Main body width Height Length TZ type 25 25 20 30~500 1,500 - -Certified by the Public Buildings Association

- -Standardized by the Ministry of Land, Infrastructure, Transport and Tourism(W25)

-

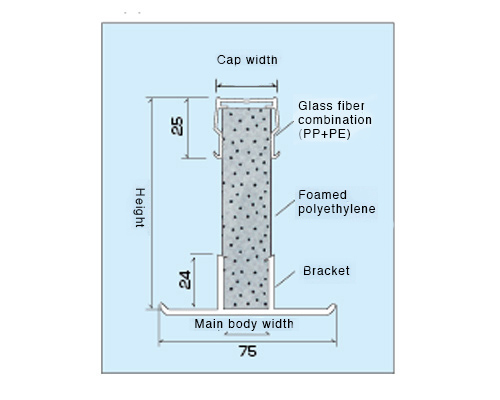

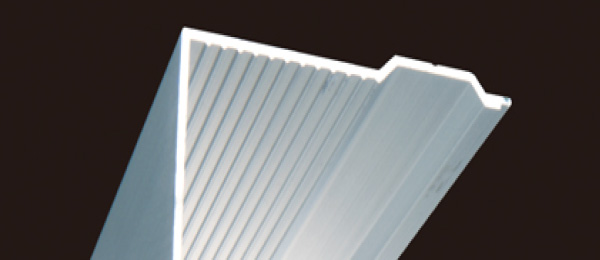

EXPANTAY TJ type

Joint filler with shape stability and workability improved

Combination of glass fibers improves shape stability, reduces shrinkage and warpage, and increases impact resistance.

The cap, which can be cut with a cutter, increases workability. This preformed expansion joint filler allows for workability and economical efficiency.Anchor type

- Principal use

- General buildings / Floors (concrete slabs)

- Major performance

- Shape stability / Impact resistance / Workability

- Accessories

- Straight-line joints (one per 1.5m) / Brackets (three per 1.5m)

Standards (Unit: mm) Product name Cap width Main body width Height Length TJ type 20 20 16 30~500 1,500 TJ type 25 25 20 TJ type 30 30 25 H100 or greater/gray cap made to order

- -Certified by the Public Buildings Association

- -Standardized by the Ministry of Land, Infrastructure, Transport and Tourism (W25)

-

EXPANTAY TX type

Anchor type joint filler that allows vehicle travel

Combination of glass fibers improves dimensional stability and decreases warpage and shrinkage. The anchor type allows for vehicle travel. In order to produce higher anchor effects, the anchor part is made large. The TX type released to satisfy market needs is an ideal joint filler having a wide range of uses and performance capabilities.

Anchor type

- Principal use

- General buildings / Parking lots (vehicles allowed)

- Major performance

- Wear resistance / Vehicles allowed (at slow speeds) / Excellent durability

- Accessories

- Straight-line joints (one per 1.5m) / Brackets (three per 1.5m)

Standards (Unit: mm) Product name Cap width Main body width Height Length TX type 25 25 20 30~500 1,500 -

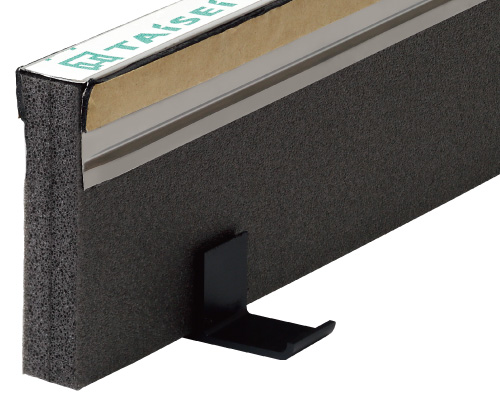

EXPANTAY STL-B type

Long-lasting beauty and outstanding integrity

Since it is made of stainless steel, it keeps shining beautifully without rusting, and is tough and excellent in integrity. This product was developed to satisfy multiple demands including covering the shortcomings of plastic joint fillers. (Stainless steel SUS304 used)

Adhesive layer type

- Principal use

- Places where gasoline, oil, chemicals, etc., are in heavy usage (vehicles allowed)

- Major performance

- Vehicles allowed / Wear resistance / Excellent durability

- Accessories

- Straight-line joints / Brackets

Standards (Unit: mm) Product name Cap width Main body width Height Length STL-B type 20 20 16 30~500 1,500 Made to order

-

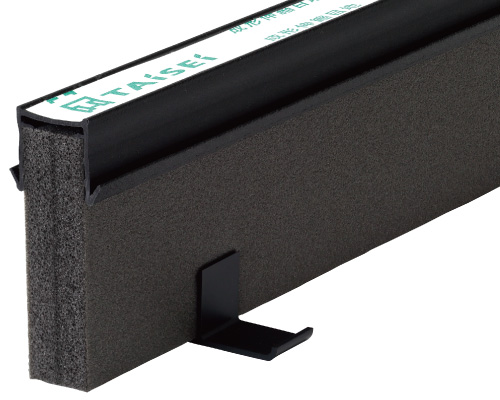

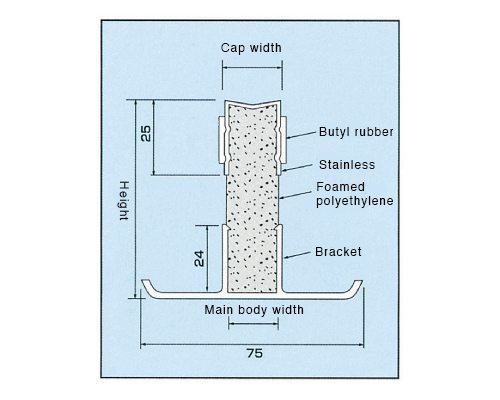

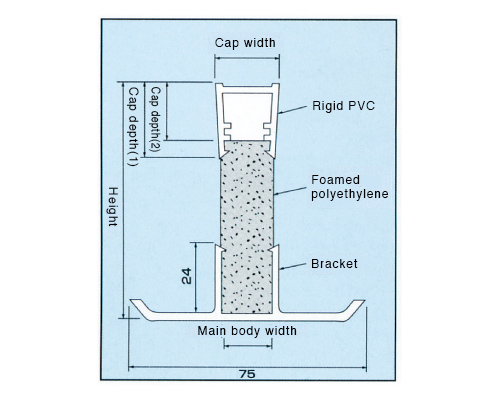

EXPANTAY TW type

Working efficiency can be remarkably improved

Since the TW type is assembly-finished, work periods can be shortened and working efficiency can be remarkably improved compared with the conventional field assembly type. Since it is lightweight, its handling is smooth, and also the finish maintains a linear beauty. The polyethylene main body will never melt under heat.

Sealing type

- Principal use

- Floors and other places where high waterproofing performance is required(vehicles allowed)

- Major performance

- Wear resistance / Vehicles allowed (at slow speeds) / Excellent durability

- Accessories

- Straight-line joints / Brackets

Standards (Unit: mm) Product name Cap width Cap depth 1 Cap depth 2 Main body width Height Length TW type 10 10 15 5 8 40~500 1,500 TW type 20 20 23 17 10 TW type 25 25 24 17 16 TW type 30 30 23 17 20 Made to order