-

Expansion joint filler construction

Expansion joint filler construction

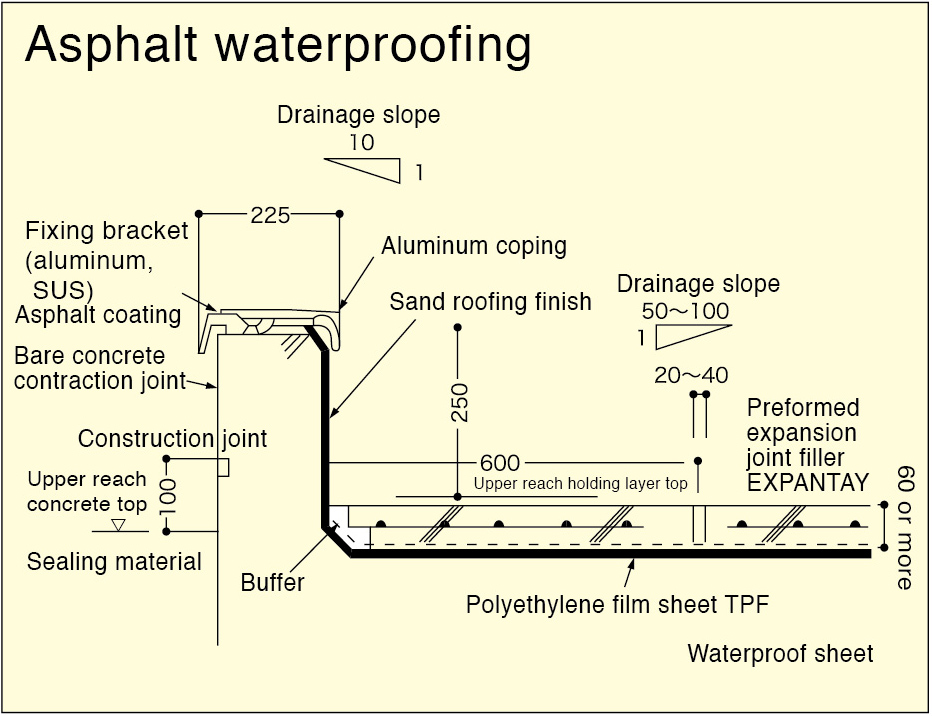

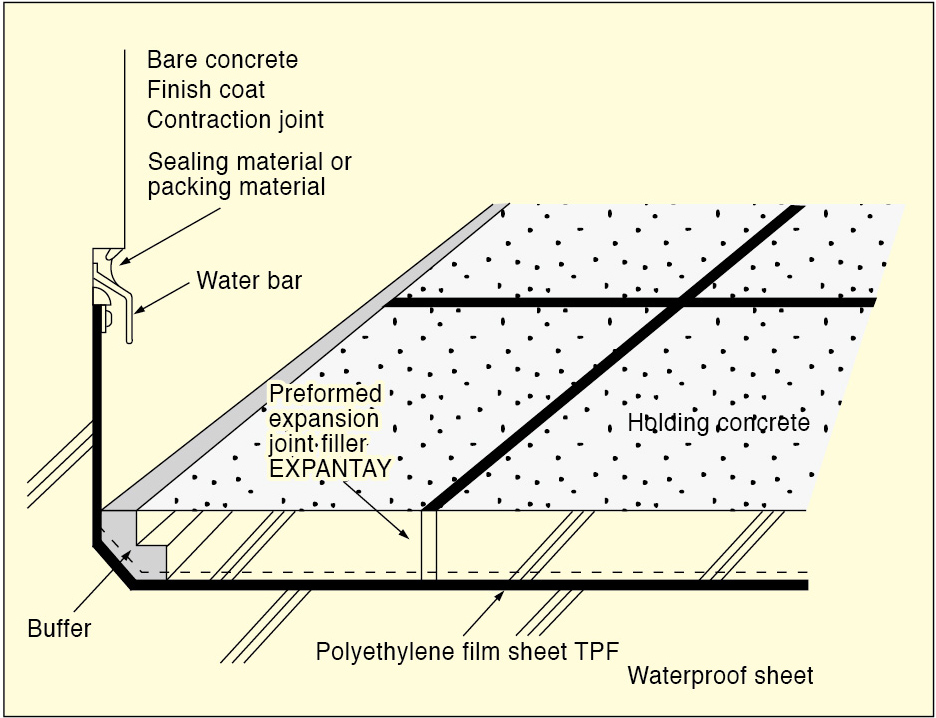

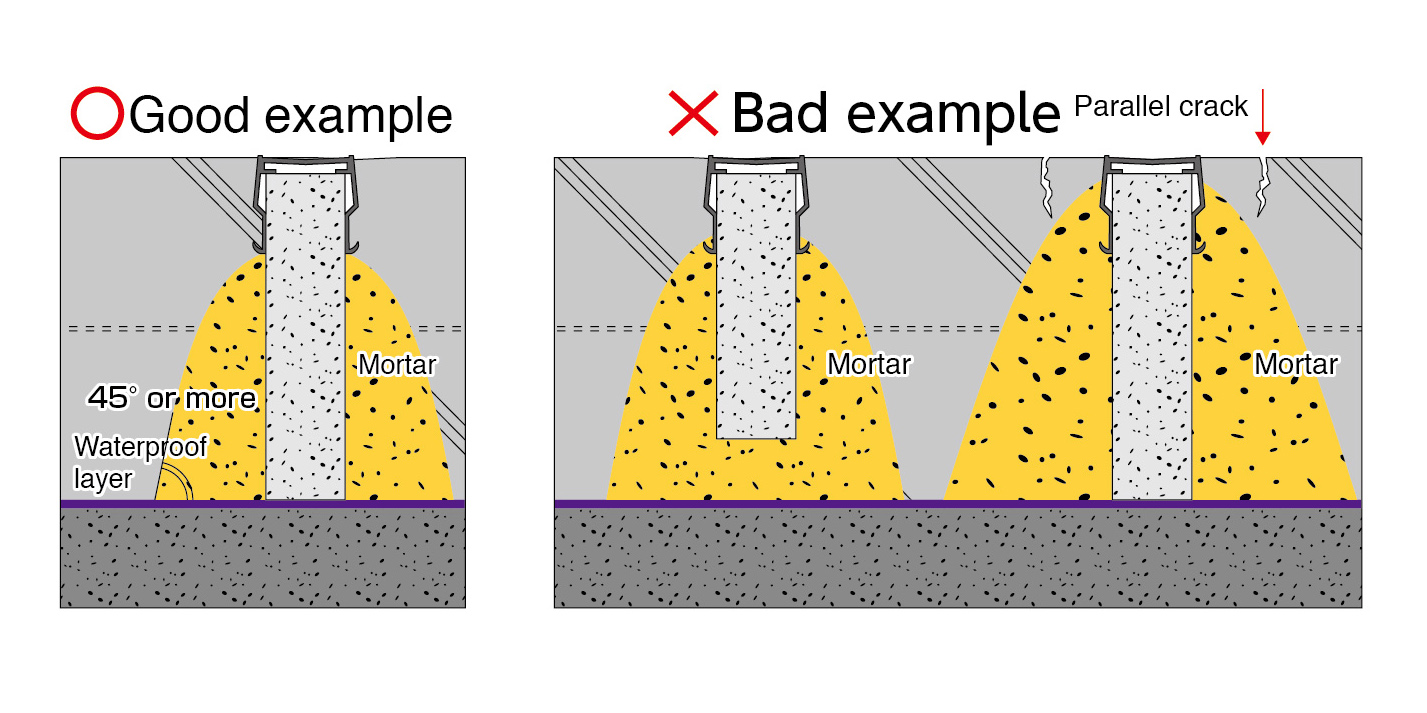

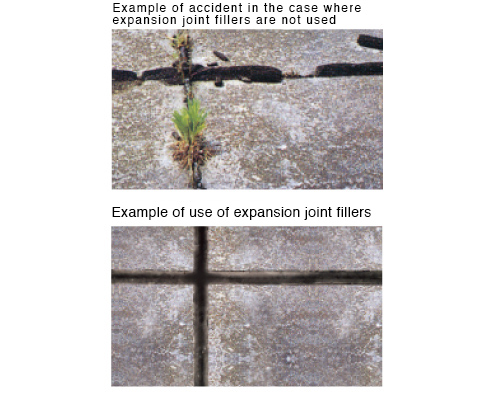

It is desirable that the holding-layer joints and finishing-layer joints are uniformly laid out as they pass through from top to bottom, and the parts surrounded by joints become completely partitioned blocks. If joints do not enter all across the cross section of the holding layer, the holding concrete under the joints will connect, and when the holding concrete expands in summer, the parapet will be pushed out and the exterior will be destroyed, causing accidents without exerting any effect. (See the illustrations.)

* EXPANTAY can be freely adjusted in height to uniformly pass through from top to bottom, allowing isolation. -

Waterproofing holding

Being careful not to damage the waterproof layer, hold the ends with special care. It is a well-known fact that the waterproofing holding layer expands to push out the parapet, damaging the exterior, cutting the waterproof layer, and causing water leakage. Most accidents caused by waterproofing holding are considered to be preventable by construction with careful consideration given to high-quality expansion joints.

-

Joint layout

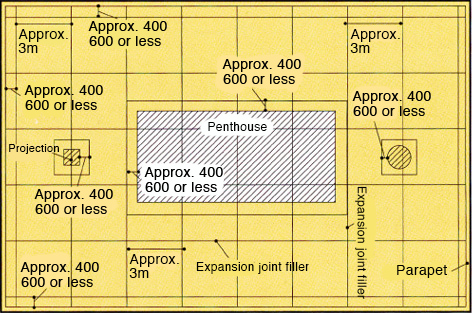

To hold rooftop waterproofing layers, near the rises around the holding concrete (lightweight concrete and aerated concrete), provide joints parallel (between 400mm and 600mm) to their finishing faces, and with longitudinal and transverse spacing of approx. 3m in other parts to reach the periphery. The finished joint width is 10 – 30mm (20mm as standard). (See the design and layout illustration.)

* EXPANTAY is easy to set and work because its width is 20 – 40mm and its length is 1.5m. -

Joint material

Expansion joint fillers that must be selected are those with increased adhesive power in holding concrete, excellent in weather resistance and temperature characteristics, and sufficiently elastic. With asphalt taken for granted, high-polymer materials are especially excellent; therefore, it is desired to select and use high-polymer materials for expansion joints.

Currently, throughout the building industry and among designers, it is said that embedding elastite is not preferable and it should be avoided where possible.

* EXPANTAY is mostly made of high-polymer materials. -

Drainage slope

Generally, it has been common up until now to use protection mortar after waterproofing work in the case of walking waterproofing holding concrete construction. Recently, however, there has been a tendency to finish holding concrete directly with a trowel.

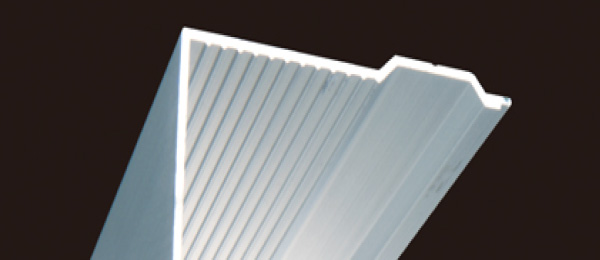

Since both ends of EXPANTAY are made of rigid PVC for good troweling, its construction is much easier with a beautiful finish compared with other products.

Although it is ideal to slope for drainage with a slab surface, since its construction is difficult, there are many cases where the drainage slope is taken by holding concrete.

* Most accidents of pushed-out parapets and water leakage that have frequently occurred up until now are eliminated by using EXPANTAY. The main reason for this is that one block between joints is finished smoothly, resulting in good drainage, with no puddles of rainwater and meltwater. In the case of asphalt and elastite construction, the surface layer floats up due to expansion during the hot season, resulting in puddles, while the top layer freezes during the cold season. EXPANTAY is characterized by not only these functional features but also its very beautiful finish. -

Design and layout

Though there are many cases where it differs with rooftop sizes and shapes of buildings, the general layout is as follows:

-Locate approx. 600mm from the finishing faces, such as surrounding rises.

-Reach the periphery (parapet) with the longitudinal and transverse spacing of approx. 3m in the middle.

* In accordance with the construction work execution management guidelines and JASS. -

Advantages and disadvantages of materials

Item name Advantages Disadvantages Description Butyl rubber Good flexibility, adhesiveness, and water resistance. Sensitive to weather and ozone, causing localized necking. Soft.

Protect from ozone and prevent localized necking by blocking sunlight and outside air with soft/rigid PVC. EPDM rubber Usable at high temperatures for a longtime for which rubber is not durable. Sensitive to mineral oil.

Sensitive to flame.Cover with rigid PVC because it is too soft to secure linear beauty by itself. Rigid PVC Excellent in weather resistance and chemical resistance, colorful, and offers a freestyle. Sensitive to shocks.

Hard.Cover with soft PVC and rubber, etc., to make up for weaknesses. Soft PVC Excellent in chemical resistance, colorful, and offers a freestyle. Sensitive to weather.

Difficult to take straight lines.Make up for softness with rigid PVC to derive straightness and strength. Polyethylene Excellent in repulsive elasticity, does not absorb water. Sensitive to ultraviolet rays. Keep characteristics semipermanently by blocking ultraviolet rays with soft/rigid PVC and butyl rubber. PP

(polypropylene)Sealable.

Resistant to low temperatures. (Cold resistance)

Dampproof, and heatproof.High contraction temperature.

Cannot be molded.Following concrete movements and having flexibility and strength.