Aluminum angles, coping, anchor plugs

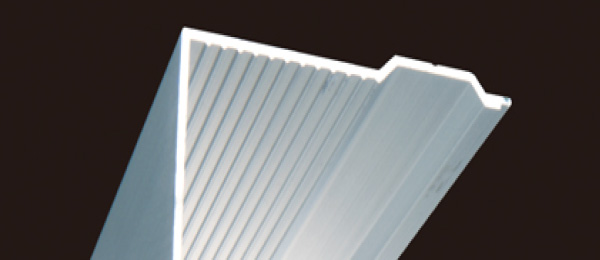

Guard-coping

New standard aluminum coping supporting our lives

As architectural styles have changed throughout history, materials have correspondingly changed from wood, stone, concrete, steel, and other materials. Against this backdrop, guard-coping is a new type of aluminum coping developed by concentrating our unique technologies to meet diversified customer needs.

///Points of guard-coping///

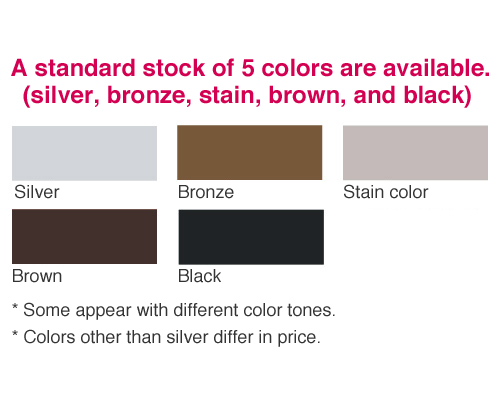

- 1. Standard stock of five colors to fit each design.(Inventory check is required except for silver)

- 2. The surface treatment of R-bent coping is the same as the straight-line type. The standard delivery time is about three weeks.

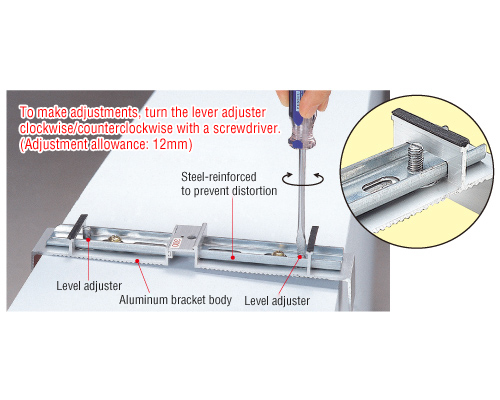

- 3. Brackets are steel-reinforced. Respective types have their distinctive characteristics, which are different in strength and quality.

- 4. There are 18 varieties of type C and 5 varieties of type U, which can be used for a wide range of applications.

- 5. Type U is a product that complies with common specifications by the Ministry of Land, Infrastructure, Transport and Tourism.

Details

-

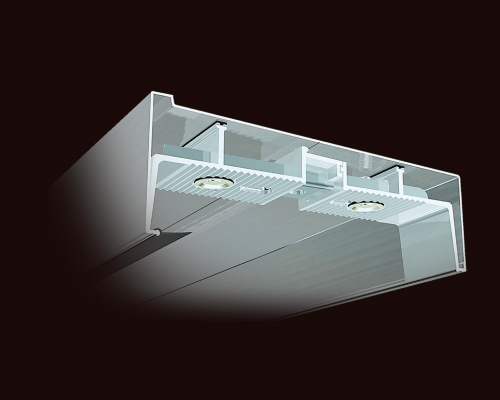

Guard-coping C・U

Ease in handling and high quality

Conventionally, coping has been mostly made of wood. As architectural styles have changed throughout history, materials correspondingly changed from stone, concrete, steel, and other materials. These days, coping made of aluminum, which is lightweight, durable, and repeatedly recyclable, is predominant. Guard-coping is a new type of aluminum coping developed by concentrating our unique technologies to meet diversified customer needs.

JIS H 4100 A-6063S-T5 (For the 12 varieties of 135 – 400, aluminum alloy extruded section bars are used. The 6 varieties of 425 – 600 are finished products of section bars and plates in combination.)

- Surface treatment

- A1 and A2 (combined coating of anodic oxide and organic films) specified by JIS H 8602:2010 or equivalent specifications

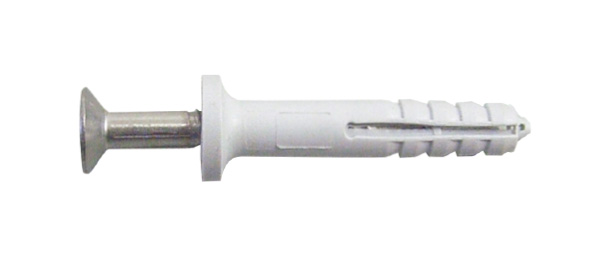

- Construction

- The main bodies and corners are mounted by snapping them into the brackets outfitted to the framework. Each joint plate is mounted by fitting it to the joint part.

- Transportation

- Products are tightly packaged in cardboard boxes, etc. As a rule, they are stacked flat, and trucked with care to ensure that cargo is not damaged or crushed.

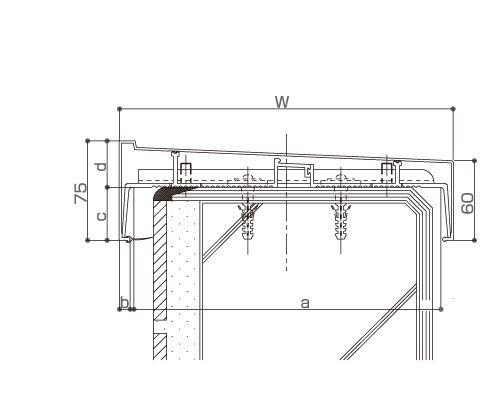

Guard-coping C

Coping Designation C-135 C-150 C-175 C-200 C-225 C-250 C-275 C-300 C-325 Dimensions (mm) a 115 130 155 180 205 230 255 280 305 b 7.3 7.3 7.4 7.8 7.8 8.2 8.3 8.4 8.7 c 40 40 40 40 40 40 40 40 40 d 35 35 35 35 35 35 35 35 35 Thickness (mm) 1.2 1.3 1.3 1.4 1.5 1.7 1.8 2.0 2.2 Length (mm) 4,000 as standard Cut length set product Main bracket 4 4 4 4 4 4 4 4 4 Joint plate 1 1 1 1 1 1 1 1 1 Joint cover 1 1 1 1 1 1 1 1 1 Plug screw 8 8 8 8 8 8 8 8 8 External undercovering 1 1 1 1 1 1 1 1 1 Adjustment plate (plastic) 16 16 16 16 16 16 16 16 16 Movement prevention screws 1 1 1 1 1 1 1 1 1 Corner Designation External corner External corner External corner External corner External corner External corner External corner External corner External corner Designation Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Dimensions (mm) 500+500 Thickness (mm) 1.2 1.3 1.3 1.4 1.5 1.7 1.8 2.0 2.2 Corner set Main bracket 2 2 2 2 2 2 2 2 2 Half bracket 1 1 1 1 1 1 1 1 1 Adjustment plate (plastic) 10 10 10 10 10 10 10 10 10 Joint plate 1 1 1 1 1 1 1 1 1 Joint cover 1 1 1 1 1 1 1 1 1 Plug screw 5 5 5 5 5 5 5 5 5 External undercovering 1 1 1 1 1 1 1 1 1 Coping Designation C-350 C-375 C-400 C-425★ C-450★ C-475★ C-500★ C-550★ C-600★ Dimensions (mm) a 330 355 380 406 430 455 480 530 580 b 8.5 9.0 9.0 8.0 8.0 8.0 8.0 8.0 8.0 c 40 40 40 40 40 40 40 40 40 d 35 35 35 35 35 35 35 35 35 Thickness (mm) 2.3 2.4 2.5 2.0 2.0 2.0 2.0 2.0 2.0 Length (mm) 4,000 as standard Cut length set product Main bracket 4 4 4 4 4 5 5 5 6 Joint plate 1 1 1 1 1 1 1 1 1 Joint cover 1 1 1 1 1 1 1 1 1 Plug screw 8 8 16 16 16 20 20 20 24 External undercovering 1 1 1 1 1 1 1 1 1 Adjustment plate (plastic) 16 16 32 32 32 40 40 40 48 Movement prevention screws 1 1 1 1 1 1 1 1 1 Corner Designation External corner External corner External corner External corner External corner External corner External corner External corner External corner Designation Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Internal corner Dimensions (mm) 500

+500700+700 800+800 Thickness (mm) 2.3 2.4 2.5 2.0 2.0 2.0 2.0 2.0 2.0 Corner set Main bracket 2 2 2 2 2 2 2 2 2 Half bracket 1 2 2 2 2 2 2 2 2 Adjustment plate (plastic) 10 12 20 20 20 20 20 20 20 Joint plate 1 1 1 1 1 1 1 1 1 Joint cover 1 1 1 1 1 1 1 1 1 Plug screw 5 6 10 10 10 10 10 10 10 External undercovering 1 1 1 1 1 1 1 1 1 * Products marked with ★ are made-to-order. The delivery time is about 10 days.

* The 12 varieties of guard-coping type C (135 – 400) are extruded section bar products.The 6 varieties of 425 – 600 are finished products of section bars and plates in combination.

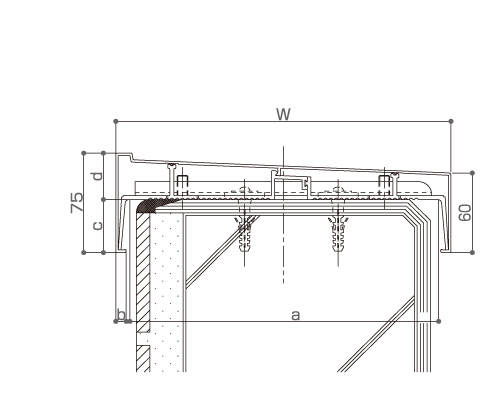

guard-coping type U

Coping Designation U-250 U-275 U-300 U-350 U-400 Dimensions (mm) a 230 255 280 330 380 b 8.2 8.3 8.4 8.5 9.0 c 40 40 40 40 40 d 35 35 35 35 35 Thickness (mm) 2.2 2.3 2.5 3.0 3.0 Length (mm) 4,000 as standard Cut length set product Main bracket 5 5 5 5 5 Joint plate 1 1 1 1 1 Joint cover 1 1 1 1 1 Plug screw 10 10 20 20 20 Corner Designation External corner External corner External corner External corner External corner Designation Internal corner Internal corner Internal corner Internal corner Internal corner Dimensions (mm) 500+500 700+700 Thickness (mm) 2.2 2.3 2.5 3.0 3.0 Corner set Main bracket 2 2 2 2 2 Half bracket 1 1 1 1 1 Adjustment plate (plastic) 1 1 1 1 2 Joint plate 1 1 1 1 1 Joint cover 1 1 1 1 1 Plug screw 5 5 10 10 12 * Products are made-to-order. The delivery time is about 3weeks.

* Guard-coping type U is made to order.

* Undercovering cannot be set to guard-coping type U.See the installation drawings of C and U series of guard-coping from here.

-

TL Series of Guard-coping

Design panels that respond to diverse applications. A wide variety of components and parts that can meet all customer’s needs.

A full variation offering sense and taste to meet all customer’s needs, such as different purposes, environments and looks.A wide variety of products so that customers can select a design that matches their site.

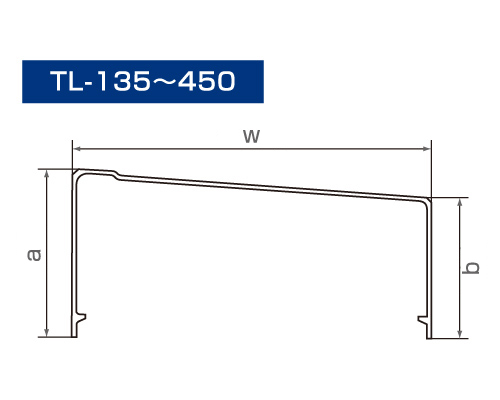

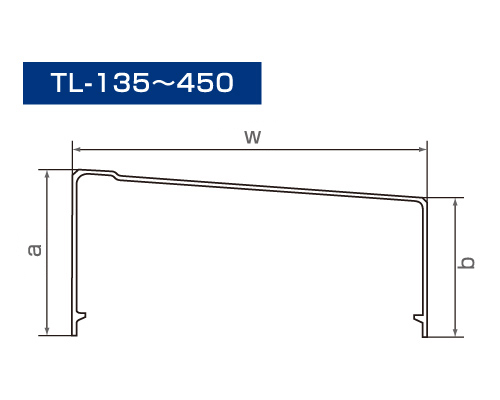

- TL-135~450

- Aluminum alloy extruded section bars (JIS H 4100-A6063S-T5) with alumite treatment of 9μ or more and clear paint treatment of 7μ or more.

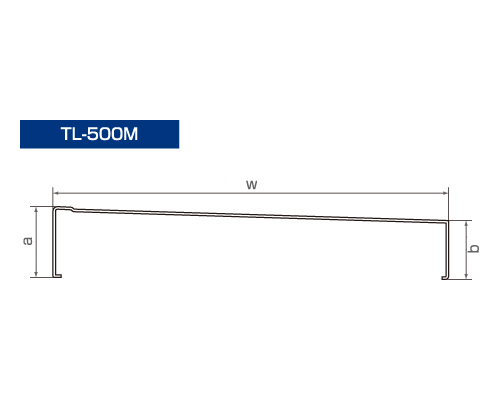

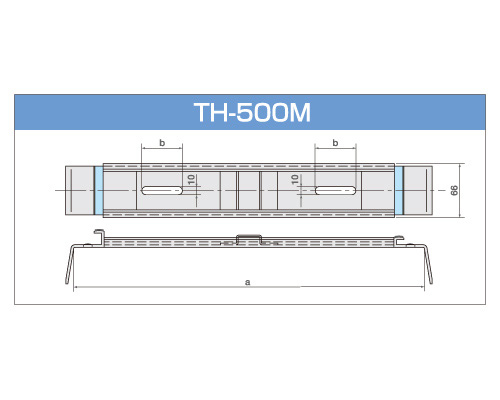

- TL-500M

- Cap and aluminum alloy plate (JIS H4000-A1100P-H14) with alumite treatment of 9μ or more and clear paint treatment of 7μ or more.

- Main bracket: Aluminum alloy extruded section bars (JIS H 4100-A6063S-T5) with alumite treatment of 9μ or more.

- Joint plate: Aluminum alloy extruded section bars (JIS H 4100-A6063S-T1) with alumite treatment of 9μ or more.

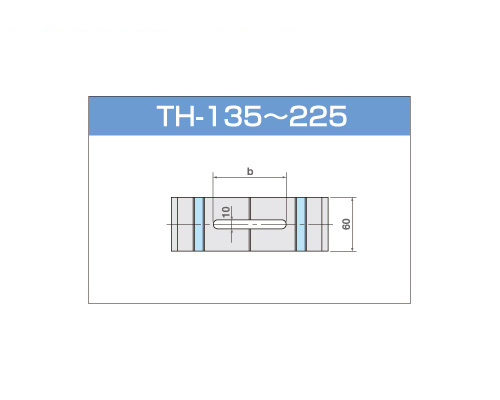

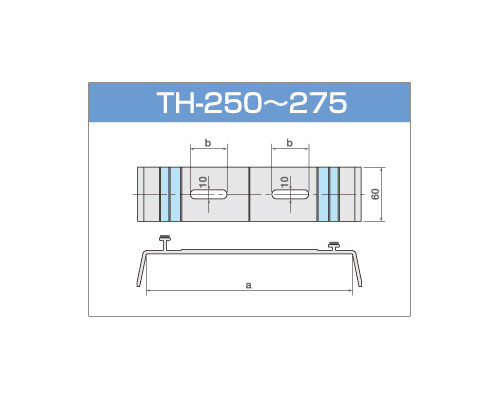

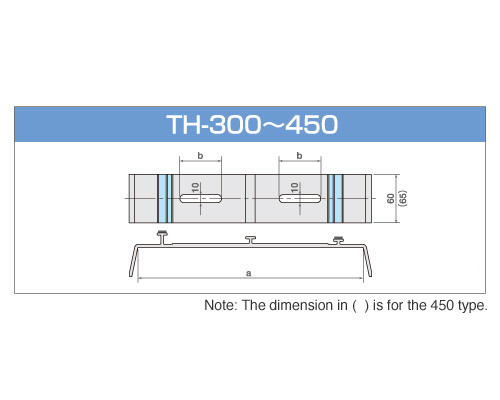

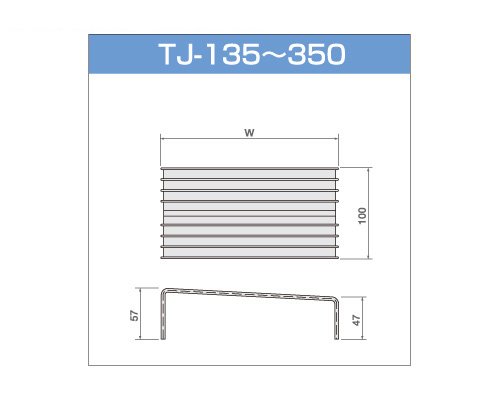

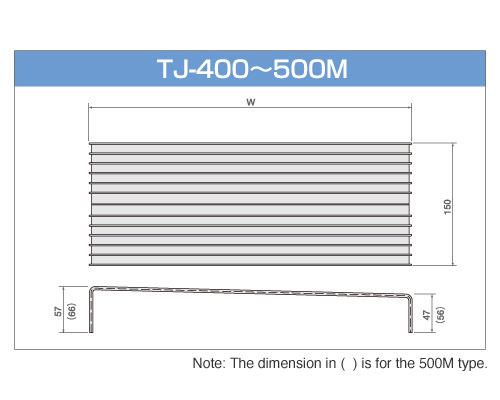

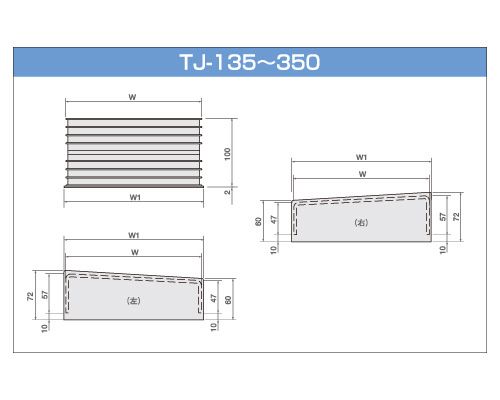

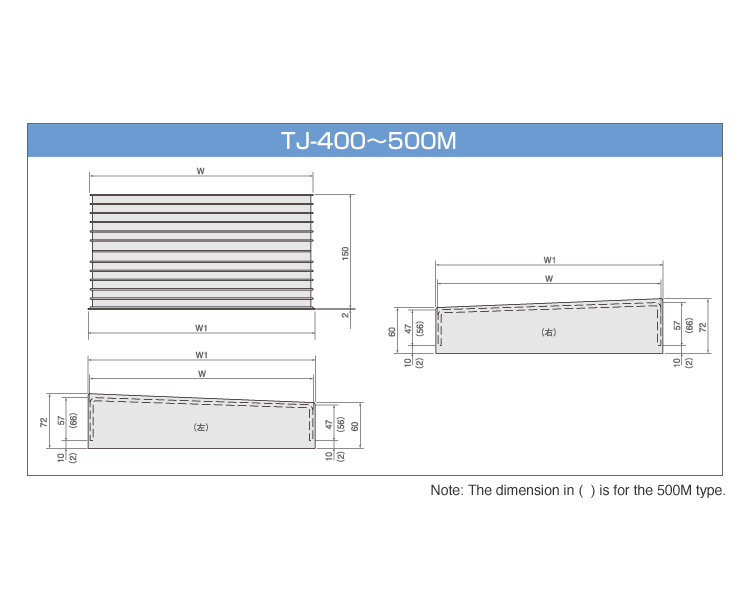

Standard Dimensions Standard Range of use of main body Guard-coping cap(TL) Main bracket(TH) Joint plate(TJ) End cap(TJ) W Thickness(t) a b w w w1 TL-135 Up to 105 135 1.3 111.3 50 60 130.4 135 TL-150 Up to 120 150 1.3 126.3 60 60 145.0 150 TL-175 Up to 140 175 1.4 151.3 80 60 170.0 175 TL-200 Up to 165 200 1.5 175.7 80 60 195.0 200 TL-225 Up to 190 225 1.6 200.5 100 60 220.0 225 TL-250 Up to 215 250 1.8 225.1 40 60 245.0 250 TL-275 Up to 240 275 1.9 249.1 50 60 268.5 275 TL-300 Up to 265 300 2.0 274.5 50 60 293.4 300 TL-325 Up to 290 325 2.3 298.0 50 60 318.0 325 TL-350 Up to 315 350 2.0 322.9 50 60 342.0 350 TL-400 Up to 365 400 2.5 374.0 50 60 393.0 400 TL-450 Up to 415 450 3.0 422.0 50 65 443.0 450 TL-500M

(Made to order)Up to 465 500 2.0 476.0 50 66 495.0 500 The cut lengths for guard-coping caps are 4,000mm for TL-135-350 and 3,000mm for TL-400-500M.

The cut lengths for corner caps are 495×495mm for TL-135-350, 700×700mm for TL-400-450 and 800×800mm for TL-500M.See the installation drawings of TL series of guard-coping from here.

-

Guard-coping for aluminum handrails (retrofitting type)

Aluminum handrails from embedded method to retrofitting method

Previously, steel handrails were embedded in concrete because concrete and steel have the same linear expansion coefficient. However, the linear expansion coefficient of aluminum handrails is significantly different from that of concrete. Therefore, if aluminum handrails are embedded in concrete, cracks will occur in the concrete portion. Moreover, since aluminum is likely to cause alkali corrosion, if aluminum handrails are embedded in concrete or mortar containing a strong alkaline substance, durability of concrete and aluminum will substantially deteriorate. So the retrofitting method was developed. This is a unique method to secure aluminum handrails without embedding them.

Features of the retrofitting method

-All parts can be assembled on site.

-A wide veranda space, etc., can be secured since a handrail can be installed at the end of the parapet.

-Ideal for replacing handrails.

Work with high durability, safety and speed is realized with no embedding of handrails

Since the linear expansion coefficient of concrete and that of aluminum are different, if aluminum handrails are embedded in concrete, cracks will occur in the concrete portion. Moreover, since aluminum is likely to cause alkali corrosion, if aluminum handrails are embedded in concrete or mortar containing strong alkaline substance, durability of concrete and aluminum will substantially deteriorate. Therefore, in order to maintain durability of concrete and aluminum and quality of the product for a long time, as well as to enhance safety, a method that does not embed handrails is required. That is the retrofitting method.- Features of handrails

- The angle can be adjusted by up to 6 degrees.

- The level can be adjusted by up to 15mm.

- The retrofitting method allows for shortening of the construction period and cost reduction.

See the installation drawings of Guard-coping for aluminum handrails from here.